MXET 375 Final Project

DC Motor Powered Crane

Model Analysis

The purpose of this project was to build a physical system that would take measurements (data points) of key variables with respect to time with real-time sensors which could then be analyzed. In addition to the construction of the physical system, the dynamic system was modeled in MATLAB using Simulink. The model parameters were calibrated using the parameters estimation toolbox in Simulink. Thereafter, the physical data captured from the physical system was compared to the simulated data from the simulated system.

Team: Aaron Luna, Luke Baber, Cody Pursifull, and Luis Luna

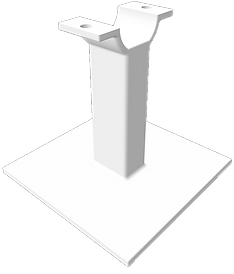

Physical Structure

The physical structure was 3D modeled using Creo 6. Cody Pursifull mainly assisted in designing the physical structure and I helped refine the geometry of the structure. The physical parts to the left are the final models which were printed in PLA. The whole physical system was assembled onto a stable wooden base. In addition, aluminum rods and bearings were installed to assist in minimizing friction. This was done to obtain better results.

Programming

& Electrical

On the image to the right is the block diagram for the Crane program. The schematic of the circuit for the physical model is shown in the image below. The electrical segments of this project can be found in the links below.

Simulation

I was mainly tasked with designing the physical system in MATLAB using Simulink. The simulated data obtained matched the physical data (experimental) with an accuracy of over 90%. Our percent errors were quite small. To the left can be seen a pair of graphs which show the simulated and physical (actual) data collection for the current drawn by the motor and RPMs of the motor. The final block diagram of the simulation can be found in the link below.

Complete Physical Model